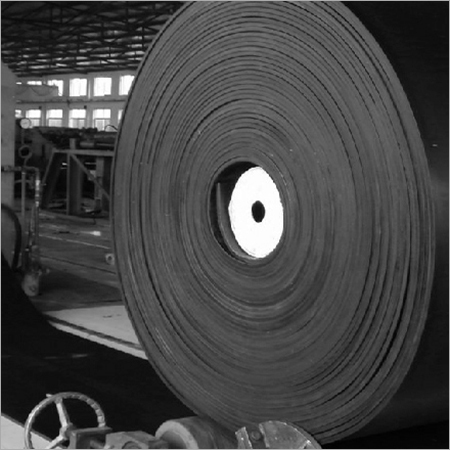

Straight Warp Conveyor Belts

Straight Warp Conveyor Belts Price And Quantity

- 0.5 Ton

- 70.00 - 600.00 INR/Ton

Straight Warp Conveyor Belts Trade Information

- Cash Advance (CA) Cheque Telegraphic Transfer (T/T) Cash in Advance (CID)

- 300 Ton Per Month

- 1 Week

- Yes

- Contact us for information regarding our sample policy

- Australia Western Europe Middle East Central America South America Asia Eastern Europe North America Africa

- All India

Product Description

INDUS SUPER SPINE is the world standard in heavy-duty industrial conveyor belts. Its innovative, straight-warp carcass construction surpasses traditional multiply belts in virtually every respect, creating a belt that has outstanding operational performance over a long life span. A single INDUS SUPER SPINE ply more than matches the strength of several traditional multi-ply layers.

The straight polyester (E) warp threads lie in the direction of belt travel, as do the polyamide (P) weft threads. Both are joined together by an additional binder yarn made of polyester(P). The strands are completely straight in both directions and are therefore not intertwined unlike traditional woven carcasses. This results in maximum protection of the warp through the weft, with minimal stretch, both lengthwise and crosswise. As there are no multiple plies, the result is a lightweight belt.

Benefits of Straight Warp Conveyor Belts

- Impact resistant

- Strong adhesion

- Good flexibility

- Light weight

- Stable working tension

- Excellent troughing

- Lower thickness

- Low elongation

- Longer roll length

Superior Impact Resistance: When compared to conventional multiply belts with a similar tensile strength, INDUS SUPER SPINE stands out with its superior impact resistance. The maximum impact energy of a single ply INDUS SUPER SPINE type 630/1 is comparable to that of a 4-ply EP belt type 1600/4.

Superior Rip Resistance: INDUS SUPER SPINE has a rip resistance that is more than four times greater than conventional multiply belts that have a similar tensile strength. The rip resistance is not only superior in relation to the multiply EP belts, but also when compared to Solid Woven.

Superior Tear Resistance: The tear resistance of INDUS SUPER SPINE also leaves conventional multiply belts with a comparable tensile strength far behind. The tear resistance is measured according to the international ISO 505 standard.

Lower Belt Weight: When compared with the belts having the same grade of the tensile strength, the SW belt provides 5% to 20% lesser weight leading to power saving. INDUS SUPER SPINE is an extremely cost-effective solution. A lighter belt type can be used in many applications due to its excellent operational characteristics and finger splice efficiency. The combination of these factors has been proven to result in exceptionally low operating costs per ton.

Lower Belt Thickness: The carcass thickness of both INDUS SUPER SPINE 1 Ply & 2 Ply is similar or smaller than those of comparable multiply EP conveyor belts from INDUS. For example, the INDUS SUPER SPINE 630/1 carcass has a thickness of 3.2 mm, compared to 5.0 mm for the EP 630/4. As a result, the required drum diameter may be smaller in some cases.

Straight Warp Conveyor Belts Technical Specifications

| Standard Widths | 500mm to 2200mm |

| Plys Available | 1 or 2 Straight Warp (SW) Plies |

| Standard Belt Rating | 400/1, 500/1, 630/1, 800/1, 800/2, 1000/2, 1200/2, 1600/2 |

| No. of Plys | 1 Ply and 2 Ply belts |

| Rubber Cover Thickness | Min 4mm Top & 3mm Bottom |

| Colour | Black |

| Edge | Cut Edge / Moulded Edge |

| Splicing Method | Hot / Cold / Mechanical |

| Belt Identification | A unique PAN (Product Authentication Number) at every 10 meters |

Other Products in 'Conveyor Belts' category

|

RAVASCO TRANSMISSION AND PACKING PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese